Unveiling the Dynamics of American Plastic Molds

by Jamey Koch

The thriving landscape of plastic manufacturing in the United States has paved the way for numerous advancements and innovations. Among the crucial elements in this industry are American Plastic Molds and Ultrasonic Welding, particularly prominent in Florida, a state known for its manufacturing prowess and technological advancements.

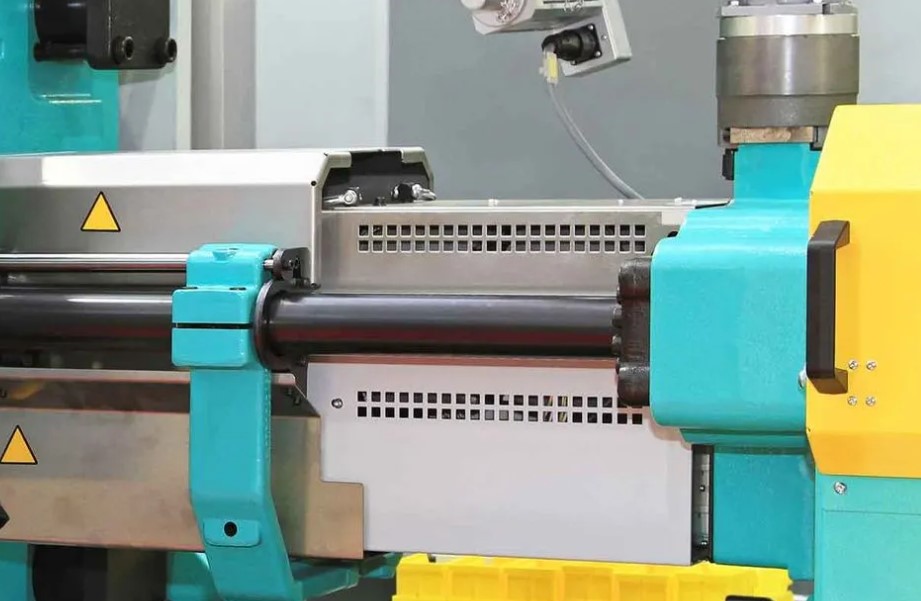

American Plastic Molds represent a vital component of the manufacturing sector, enabling the production of various plastic components and products. These molds are meticulously designed to shape and form molten plastic materials into desired shapes, catering to a broad spectrum of industries ranging from automotive and aerospace to healthcare and consumer goods.

Florida hosts a multitude of companies specializing in plastic mold creation, offering custom solutions tailored to the unique requirements of different businesses. These companies employ cutting-edge technologies and high-precision machinery to craft molds that ensure quality, consistency, and efficiency in the manufacturing process.

The pursuit of excellence in plastic molding is deeply ingrained within the American Plastic Molds industry. High-quality molds are not only essential for producing superior products but also contribute significantly to manufacturing efficiency. Precision molds reduce material wastage, minimize production downtime, and enhance overall operational productivity.

American Plastic Molds represent the fusion of artistry, engineering precision, and industrial ingenuity. Their impact spans across diverse sectors, driving progress, innovation, and economic growth. As technology continues to advance and the demand for complex and customized plastic components rises, the evolution of American Plastic Molds remains pivotal in shaping the future of manufacturing.

Ultrasonic welding has emerged as a significant technique in joining plastic components together seamlessly and securely. In Florida, the utilization of ultrasonic welding technology has gained prominence for its ability to bond thermoplastics with precision, speed, and reliability. This process uses high-frequency ultrasonic vibrations to create a strong molecular bond between plastic parts without the need for adhesives or additional materials.

Florida's manufacturing landscape benefits significantly from the expertise of professionals adept in ultrasonic welding techniques. Industries such as medical device manufacturing, automotive assembly, electronics, and packaging rely on ultrasonic welding for its ability to produce durable and high-quality plastic assemblies.

The convergence of American Plastic Molds and Ultrasonic Welding heralds a new era in plastic manufacturing. These technologies complement each other seamlessly, combining precision molding with the ability to join plastic components with unparalleled accuracy and strength. Manufacturers harness this synergy to produce complex assemblies with intricate geometries, ensuring structural integrity and reliability in the final products.

The amalgamation of American Plastic Molds and Ultrasonic Welding offers numerous advantages across various industries. Automotive manufacturers utilize this technology for producing intricate vehicle components with enhanced strength and durability. Medical device manufacturers benefit from the precision bonding capabilities for creating sterile and reliable medical equipment. Additionally, consumer electronics, packaging, and aerospace industries leverage ultrasonic welding for its ability to create seamless and secure connections in their products.

The collaboration between American Plastic Molds and Ultrasonic Welding continues to evolve, driven by technological advancements and the quest for greater efficiency and sustainability. Innovations such as the integration of robotics, advanced materials, and process optimizations are reshaping the landscape of plastic manufacturing. The future holds promising prospects for further advancements in ultrasonic welding techniques, fostering greater adaptability, and widening the scope of applications.

The Florida injection mold maintenance ensure optimal performance and longevity for the continuous usage of plastic molds and injection molding equipment. Florida offers a range of services catering to plastic mold repair and maintenance needs, including Skilled technicians and engineers in Florida specialize in repairing damaged or worn-out plastic injection molds, employing precision techniques to restore molds to their original specifications.

Florida-based companies offer comprehensive maintenance services, including cleaning, lubrication, and inspection of molds to prevent downtime and ensure consistent production. Florida is home to a diverse array of plastic mold injection companies that cater to the demand for custom solutions. These companies collaborate closely with clients to design and produce molds tailored to specific project requirements. They leverage state-of-the-art technology and expertise to create intricate molds capable of producing high-quality plastic components for various industries.

Quality assurance is at the forefront of Florida's plastic mold repair and maintenance services. The focus remains on delivering high-quality repairs and maintenance that adhere to industry standards and regulatory requirements. The aim is to ensure that repaired or maintained molds maintain their precision, durability, and reliability, ultimately contributing to the production of top-notch plastic components.

Florida's American Plastic Molds services are not stagnant but instead evolve with technological advancements. Incorporating the latest tools, technologies, and methodologies, these services from Florida injection mold maintenance continuously upgrade their approaches. This includes embracing digital technologies for diagnostics, employing advanced materials for repairs, and integrating automation for enhanced efficiency.

The symbiotic relationship between American Plastic Molds, Ultrasonic Welding, and Florida's manufacturing landscape underscores the state's significance in the plastic manufacturing industry. The convergence of cutting-edge technologies, skilled professionals, and a commitment to innovation positions Florida as a hub for the production, repair, and maintenance of plastic molds, meeting the diverse needs of industries nationwide.

About American Plastic Molds

American Plastic Molds has proudly stood as a cornerstone of the plastic manufacturing industry in Florida, catering to the needs of Miami, Broward, Palm Beach, and beyond with an unchanging dedication. We are a family-owned company with strong roots in the area and a firm commitment to providing the best plastic solutions possible. At American Plastic Molds, we pride ourselves on our unwavering commitment to excellence, which seamlessly intertwines with our utilization of state-of-the-art technology. With cutting-edge technology, such as ultrasonic plastic welding machines, we go above and beyond to ensure that our products not only meet but surpass the most stringent industry standards. Our unwavering dedication to the highest technology enables us to achieve remarkable outcomes that not only endure the test of time but also thrive under immense pressure.

Contact Information

For more information about American Plastic Molds and their services contact them at:

American Plastic Molds

Address: 764 NE 42nd Street, Pompano, FL 33064

Phone: 954-785-9989

The thriving landscape of plastic manufacturing in the United States has paved the way for numerous advancements and innovations. Among the crucial elements in this industry are American Plastic Molds and Ultrasonic Welding, particularly prominent in Florida, a state known for its manufacturing prowess and technological advancements. American Plastic Molds represent a vital component of…

Recent Posts

- Expert Cleaners Lexington Shares Essential Tips for Properly Cleaning Hardwood Floors

- Port St. Lucie Locksmith: Your Trusted Partner for Security Solutions

- Port St. Lucie Locksmith: Your Trusted Partner for Security Solutions

- Cost of Installing a Pool in Cape Coral, Florida: A Rough Guide

- Lighting Up the City with Outdoor Lighting Companies